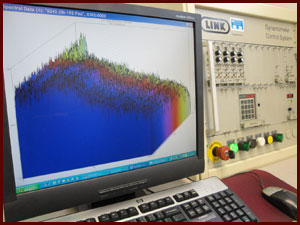

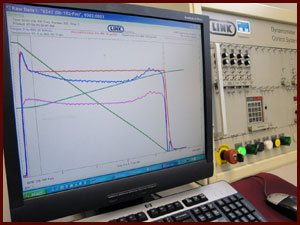

AFT operates a state of the art Research and Development facility. During the product design and development phase, real-world conditions are simulated on our in house Link Dynamometers. Dynamometer test capabilities include, but are not limited to, a Daytona 200 motorcycle race, ATPD 2354A-Jenners Town Simulation, and Class 8 on-highway truck clutch endurance testing.

To support these testing requirements, AFT prides itself on rapid turn around of prototype parts which are processed directly with the production molding, sintering and coining equipment. These methods ensure smooth production start-ups that are guaranteed to meet customer expectations. Furthermore, AFT utilizes Advance Product Quality Planning techniques for pre-production runs and has the capability for Level 3 PPAP customer submittals.

AFT is focused on quality assurance and designs it into each phase of the manufacturing process. We utilize automated production equipment and state of the art metrology within an ISO9001:2008 registered Quality Management System |